Key Takeaways

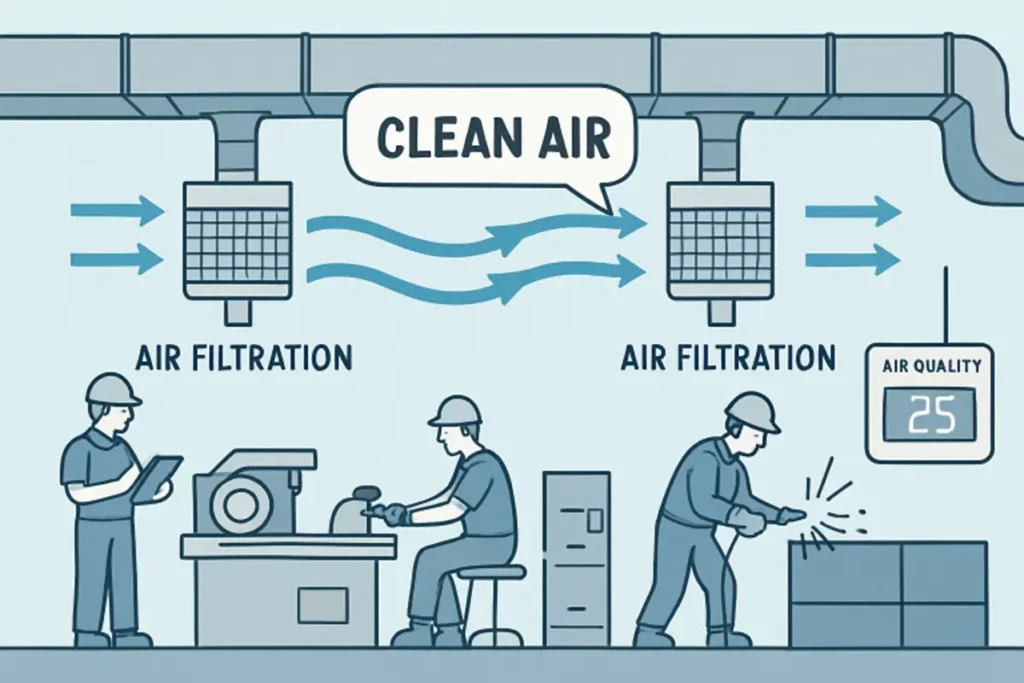

- Effective air filtration and ventilation are essential for reducing airborne contaminants in industrial workplaces.

- Proper maintenance of HVAC systems ensures consistent air quality and compliance with health regulations.

- Advanced technologies, such as IoT-based monitoring, enhance the efficiency of clean air systems.

Understanding the Importance of Air Quality in Industrial Settings

Air quality in industrial workplaces has a direct impact on the health and safety of the workforce. Dust, chemical fumes, particulate matter, and volatile organic compounds are common pollutants in these environments. Without adequate protection, workers are at risk of developing respiratory and other health issues. Selecting the right clean air system reduces exposure to harmful airborne contaminants and upholds health standards. For comprehensive air quality improvements, consulting an industrial insulation contractor experienced in industrial ventilation and filtration is a critical first step.

The dangers posed by poor air quality span from acute complications, like eye and throat irritation, to chronic diseases such as asthma and, in extreme cases, cancer. Ensuring breathable, purified air helps companies create a safe environment while meeting legal obligations for worker welfare. Furthermore, effective air management not only protects health but also mitigates odors and prevents the buildup of hazardous substances that can lead to operational disruptions.

Worker safety is bolstered by a proactive approach to identifying air quality risks. For instance, monitoring and adjusting indoor air quality prevents both immediate accidents—such as those caused by combustible dust—and long-term health issues associated with chemical exposure or inadequate ventilation. Organizations that prioritize air quality consistently outperform those that neglect it, with tangible reductions in absenteeism and workplace accidents.

In addition to protecting workers, strategic air purification also safeguards equipment and processes from the corrosive effects of airborne chemicals and particulates. This dual benefit—improved worker well-being and enhanced equipment longevity—underpins the investment appeal of quality clean air systems.

Modern industrial clean air systems are built using several integrated components that together keep workplaces healthy and compliant:

- High-Efficiency Particulate Air (HEPA) Filters: These powerful filters remove fine dust, allergens, and microbial contaminants from the air, significantly lowering exposure risks.

- Ventilation Systems: Robust ventilation continuously drains contaminated air and introduces fresh, outdoor air, diluting indoor pollutant concentrations.

- Air Quality Monitoring Sensors: These sensors track pollutant levels in real-time and trigger alerts or automated responses when conditions deteriorate. Sensors enable immediate intervention, ensuring that air quality never falls below regulatory thresholds.

Emerging technologies also play an important role. For example, electrostatic precipitators and UV-C light purification offer additional methods for removing harmful particulates and neutralizing biological hazards within air streams.

Implementing and Maintaining Clean Air Systems

Adopting clean air systems in industrial workplaces involves more than installation. Ongoing maintenance and careful oversight are vital for sustained performance:

- Conduct Regular Air Quality Assessments: Scheduled assessments pinpoint risks and inefficiencies, enabling continual improvement of air management strategies.

- Schedule Routine Maintenance: Filters, ducts, and monitoring devices require regular cleaning, servicing, and calibration to function optimally. Neglect can quickly lead to system failure and unsafe working conditions.

- Train Staff: Employees must understand ventilation protocols and the importance of promptly reporting faults or concerns about air quality.

Studies published by organizations such as the Occupational Safety and Health Administration (OSHA) show a direct correlation between routine air system maintenance and lower rates of occupational illness and regulatory violations.

Leveraging Technology for Enhanced Air Quality

With current advances in environmental technology, industrial workplaces can now benefit from intelligent air quality monitoring powered by the Internet of Things (IoT). IoT-connected sensors and automated HVAC systems continuously collect air quality data and enact dynamic adjustments based on pollutant readings. Such systems can instantly increase ventilation or activate special filtration protocols in response to toxin spikes, thus minimizing worker exposure almost in real-time.

According to a 2024 report in Scientific American, smart buildings equipped with IoT-based environmental sensors have demonstrated remarkable effectiveness in identifying pollutant peaks and initiating automatic remediation. This technology not only improves compliance but also fosters a measurable improvement in worker health and long-term organizational resilience.

Compliance with Health and Safety Regulations

Compliance with air quality standards is a legal requirement for every industrial facility. Regulations from agencies like OSHA and guidance from organizations such as the American Industrial Hygiene Association (AIHA) offer standards and checklists to help facilities ensure air safety. Leveraging these resources to create a tailored air quality management plan protects both workers and the organization’s reputation.

Any lapses in compliance can result in severe penalties, legal action, or forced shutdowns. Thorough documentation and adherence to official recommendations, such as those provided by the Centers for Disease Control and Prevention (CDC), are crucial for effective risk management and ongoing improvement.

Economic Benefits of Clean Air Systems

Beyond health and compliance, well-maintained clean air systems offer clear economic advantages for industrial operators:

- Reduced Healthcare Costs: Cleaner air means fewer employee illnesses, resulting in lower healthcare claims and insurance expenses for employers.

- Enhanced Productivity: Workers in clean air environments take fewer sick days and maintain higher levels of focus and performance.

- Regulatory Compliance: Meeting established air quality benchmarks prevents fines, legal costs, and unplanned disruptions to business operations.

Moreover, demonstrating a proactive commitment to workplace safety via proper air management bolsters an organization’s standing with leadership teams, clients, and regulatory bodies.

Conclusion

Investing in and adequately maintaining clean air systems in industrial workplaces is crucial for safeguarding employee health, complying with regulatory requirements, and achieving operational efficiencies. By integrating advanced monitoring technologies, performing regular maintenance, and adhering to best practices established by reputable health organizations, industrial facilities create safer and more efficient work environments that benefit everyone involved.

Also Read

- Tech Console DefStartup: Empowering Gaming Innovation

- Concrete vs Metal, Cementing vs Forging: Comparing JSW Steel & Ultratech

- Understanding the Role of Lawyers in Everyday Life