Table of Contents

- Introduction

- Advanced Diagnostic Tools

- Paintless Dent Repair (PDR)

- Advanced Driver Assistance Systems (ADAS) Calibration

- Use of Lightweight Materials

- Eco-Friendly Painting Methods

- 3D Printing for Part Replacement

- Mobile Repair Services

- Technician Training and Certification

As automotive technology becomes more complex, collision repair must keep pace to ensure modern vehicles are returned to their pre-accident condition safely and efficiently. Significant advances in repair methods make it crucial for drivers to stay informed when facing collision damage or looking for qualified service providers. To better understand this industry’s innovations and evolving best practices, learn more about choosing the right collision repair team and techniques for today’s advanced vehicles.

Understanding the range of new diagnostic processes, repair materials, and sustainability measures can significantly affect the quality and lifespan of collision repairs. These advancements ensure a seamless restoration of vehicle appearance and the continued reliability of critical safety features. That’s why staying up to date with the latest technological and environmental trends is crucial for drivers, technicians, and anyone invested in automotive care.

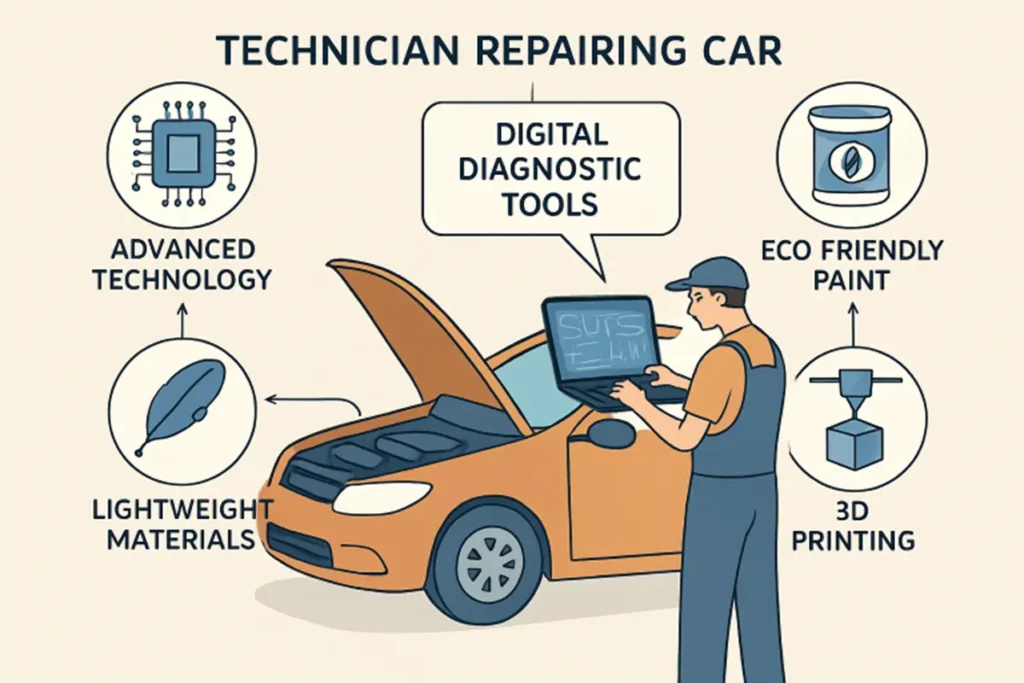

Advanced Diagnostic Tools

Today’s vehicles depend on a vast electronics network, sensors, and advanced onboard computers. These systems demand equally advanced diagnostic tools following a collision. Using computerized assessments and 3D imaging technology, technicians can unearth structural issues, misalignments, or hidden problems that were once easy to overlook. Diagnosing problems accurately from the outset leads to more precise repairs, streamlining both time and cost for vehicle owners. According to Consumer Reports, using advanced scanning tools can be pivotal in identifying otherwise invisible vehicle safety risks.

Paintless Dent Repair (PDR)

The rise of Paintless Dent Repair (PDR) offers drivers a rapid, eco-friendly option for addressing minor dings and dents, especially from hail or parking mishaps. Unlike traditional repairs that require sanding, filling, and repainting, PDR relies on specialized methods to gently massage the dented metal back to its original shape, maintaining the factory paint finish. This preserves the vehicle’s value and paint integrity and drastically reduces repair time and environmental impact.

Advanced Driver Assistance Systems (ADAS) Calibration

With ADAS becoming standard in most vehicles, proper recalibration after a collision is essential. Features such as automatic emergency braking, adaptive cruise control, and lane departure warnings rely on precisely aligned cameras and sensors. If these components shift even slightly during an accident, the systems may malfunction, endangering the driver and others on the road. Expert recalibration ensures all ADAS features operate correctly, restoring safety and driver confidence.

Use of Lightweight Materials

Integrating lightweight materials—such as aluminum, carbon fiber, and high-strength steel—allows automakers to improve fuel efficiency and overall vehicle performance. However, these modern materials also require specialized repair knowledge and equipment. Unlike traditional steel, advanced composites demand careful handling and specific repair processes to maintain strength. Professional shops invest in ongoing technician training to manage the challenges and ensure safety standards are met during complex repairs.

Eco-Friendly Painting Methods

Today’s repair shops are adopting new painting systems that minimize emissions and reduce the environmental footprint of collision repairs. Water-based paints are growing in use, replacing older solvent-based options. Energy-efficient curing techniques, such as UV-cured clearcoats, further promote sustainability. These changes benefit the environment and vehicle owners seeking greener repair options, aligning with increasingly rigorous regulatory demands and customer preferences.

3D Printing for Part Replacement

Technological innovation in 3D printing is rapidly reshaping the ability of repair shops to source or fabricate parts. If original components are out of stock or unavailable, 3D printing allows on-demand production of high-quality, customized parts. This cuts down on wait times and helps ensure a precise fit for older models or specialty vehicles, often at a reduced cost compared to traditional ordering channels.

Mobile Repair Services

Mobile repair solutions have surged in popularity as consumers demand more convenience. Equipped with the necessary tools and equipment, technicians can perform various repairs right at the customer’s home or office, including minor bodywork, windshield replacements, or paint touch-ups. This flexible service reduces vehicle downtime, increases customer satisfaction, and often comes with competitive pricing due to lower shop overhead.

Technician Training and Certification

Modern collision repair shops recognize that staying ahead means investing in technician expertise. Continuous education and certification programs, such as those from I-CAR or ASE, keep technicians updated on evolving vehicle designs, electronics, and materials. When choosing a repair center, looking for certified professionals ensures every repair’s integrity, safety, and long-term reliability.

For today’s drivers, understanding developments in collision repair fosters better decision-making and peace of mind after an accident. Embracing these innovations ensures safer vehicles, environmental responsibility, and exceptional results for every repair.

Also Read-Determining the Value of a Car