Post Preview

Key Takeaways

- UV LED printing ensures instant ink curing, streamlining production and improving print quality.

- This method accommodates many substrates, including sensitive materials previously unsuitable for traditional approaches.

- Substantial energy savings and reductions in environmental pollutants distinguish the technology.

- Wide-ranging applications have made UV LED printers indispensable in sectors such as signage, packaging, décor, and product personalization.

- Emerging trends focus on sustainability, enhanced automation, and compatibility with even more substrate types.

Table of Contents

- Summary

- Introduction to UV LED Printing

- Advantages of UV LED Printing

- Diverse Applications of UV LED Printing

- Future Trends in UV LED Printing

- Conclusion

Summary

Printing has come a long way from its early mechanical roots, evolving into a field driven by innovation and precision. Today’s market demands visual quality, faster turnaround times, and environmentally responsible processes. This shift has paved the way for groundbreaking solutions that meet modern needs without compromising performance. UV LED printing technology fundamentally reshapes the printing landscape with its unique speed, versatility, and sustainability blend. As more industries seek fast, high-quality, and customized print solutions, the adoption of UV Printers has surged, offering capabilities far exceeding those of traditional systems. These advanced printers harness the power of ultraviolet light-emitting diodes (UV LEDs), enabling instant ink curing and broadening the range of printable substrates.

Unlike conventional print methods relying on time-consuming solvent evaporation, UV LED printing allows immediate handling, increased productivity, and minimized environmental impact. Companies of all sizes benefit from reduced energy consumption, near-zero emissions, and the ability to print stunning, durable graphics on everything from packaging to textiles. As global demand grows for efficient and greener solutions, UV LED printing stands out as a cornerstone technology driving innovation across the printing industry.

Introduction to UV LED Printing

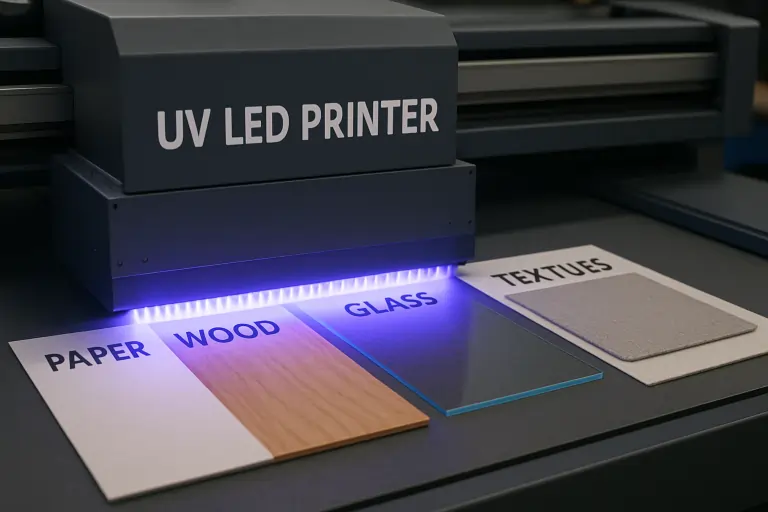

UV LED printing is a highly efficient process that utilizes ultraviolet lights to cure specially formulated inks instantly. This transformative technique addresses some of the most pressing challenges in traditional printing, such as excessive drying times, limited substrate compatibility, and high operational costs. By applying ink directly to the chosen material and immediately hardening it with UV exposure, UV LED printers deliver vibrant, precise, and long-lasting results regardless of material limitations.

Recent advancements have made this technology accessible to businesses of all sizes, offering cost-effective options that make high-quality printing feasible for diverse industries. The flexibility and minimal maintenance required by UV LED printing have allowed organizations to respond swiftly to market opportunities and provide premium services to their clients.

Advantages of UV LED Printing

- Instantaneous Drying: The most prominent benefit of UV LED printing is the immediate ink curing. Products can be handled or shipped without delays for drying or off-gassing, drastically reducing turnaround times.

- Enhanced Substrate Variety: UV LED systems excel on unconventional and heat-sensitive materials, such as thin films, plastics, glass, wood, ceramics, and textured surfaces, leading to breakthrough applications in branding and manufacturing.

- Energy and Cost Savings: UV LED printers consume significantly less power than traditional mercury-vapor lamp systems, which translates into direct energy and operational cost reductions and extended equipment lifespan.

- Eco-Friendly Printing: VOC emissions are notably reduced due to the absence of solvent-based inks and mercury lamps. This move toward greener technologies helps companies meet regulatory demands and improve workplace safety.

- Superior Durability: UV-cured prints resist scratches, moisture, chemicals, and UV exposure, ensuring high-quality results even in extreme applications or external environments.

Diverse Applications of UV LED Printing

UV LED printing’s flexibility allows it to support multiple market sectors:

- Advertising and Signage: Full-color, UV-stable graphics are ideal for indoor and outdoor displays, delivering impactful advertising with enhanced durability.

- Packaging and Labeling: UV LED technology enables rapid, customized short-run packaging and detailed labels that feature sharp images, variable data, and tactile finishes.

- Interior Décor: Direct printing on wood, glass, tiles, and acrylic panels empowers architects and designers to create one-of-a-kind interior solutions, branded fixtures, and decorative accents.

- Personalized Consumer Goods: Businesses can offer bespoke products like drinkware, apparel, tech accessories, and promotional items, allowing customers to create unique branded experiences.

UV LED technology is critical in reducing waste and meeting the increasing market demand for individualized products by facilitating on-demand production and precise customization. According to FESPA, the versatility of UV LED systems is fast-tracking the adoption of digital solutions across multiple print sectors, with an increasing focus on sustainability and high-speed output.

Future Trends in UV LED Printing

- Sustainability Innovations: The print industry’s commitment to sustainability drives new developments in eco-friendly UV-curable inks, recycled substrates, and even lower-energy curing systems. These enhancements help organizations meet strict environmental benchmarks.

- Smart Automation and Intelligence: AI-powered print management, IoT-enabled printers, and self-calibrating systems are emerging. Such innovations promise to minimize material waste, enhance precision, and ensure consistent high-quality output without constant human oversight.

- Expanded Material Range: Next-generation UV inks and adaptive curing systems are broadening application possibilities, supporting everything from metallic surfaces to flexible electronics and specialty composites.

- Intersection with 3D Printing: UV LED curing is increasingly being incorporated in additive manufacturing, supporting the rapid prototyping of multi-material objects, components, and microstructures in industries as varied as automotive, aerospace, and healthcare.

A recent MTuTech analysis highlights the rapid integration of automated digital platforms with sustainable UV LED systems as a driving force for future market growth, especially as consumers and enterprises move toward eco-conscious, on-demand print solutions.

Conclusion

As UV LED printing technology advances, its influence on the printing industry is becoming increasingly profound. This innovative approach offers unmatched speed, precision, and adaptability, allowing printers to work on a wide range of materials, including glass, metal, wood, and plastics, without requiring extensive pre-treatment. Its instant curing process accelerates production and reduces energy consumption, contributing to a smaller environmental footprint. These efficiencies allow businesses to expand into lucrative markets such as high-quality commercial graphics, customized promotional products, and intricate specialty packaging. Additionally, the technology’s ability to deliver vibrant, long-lasting prints meets the’ rising demand for quality and sustainability in consumer goods. Companies that adopt UV LED printing are enhancing productivity and future-proofing their operations, positioning themselves to stay ahead of evolving market trends, exceed customer expectations, and maintain a competitive edge in an increasingly eco-conscious and fast-paced industry.

Read more: The Greatest Sectional Sofa Designs for Modern Living Areas – Trend Oxygen

Exploring The Recreational Amenities of Saffron City

What Sets SBI and Tata Mutual Funds Apart in Strategy?